Day One - Katie Anderson's Japan Study Trip

Having been rerouted through Guam to reach Narita, I finally arrived in Nagoya on Sunday. We met Isao Yoshino on Monday morning as part of Katie's Leaning to Lead, Leading to Learn book. For over 40 years, Isao Yoshino held various managerial positions. Mr. Yoshino oversaw NUMMI's manager training program. The Kanri Nouryoku (Kan-Pro) program was one of Mr. Yoshino's most notable contributions to Toyota. Using A3 as the standard method for problem-solving was popularized through this manager development initiative. Mr. Yoshino gave us some amazing insights in his lecture on Toyota managers.

Isao Yoshino’s Morning Lecture

Here are some interesting takeaways:

At Toyota, planning and doing were less critical than checking (PDCA). Learning takes place during the check phase.

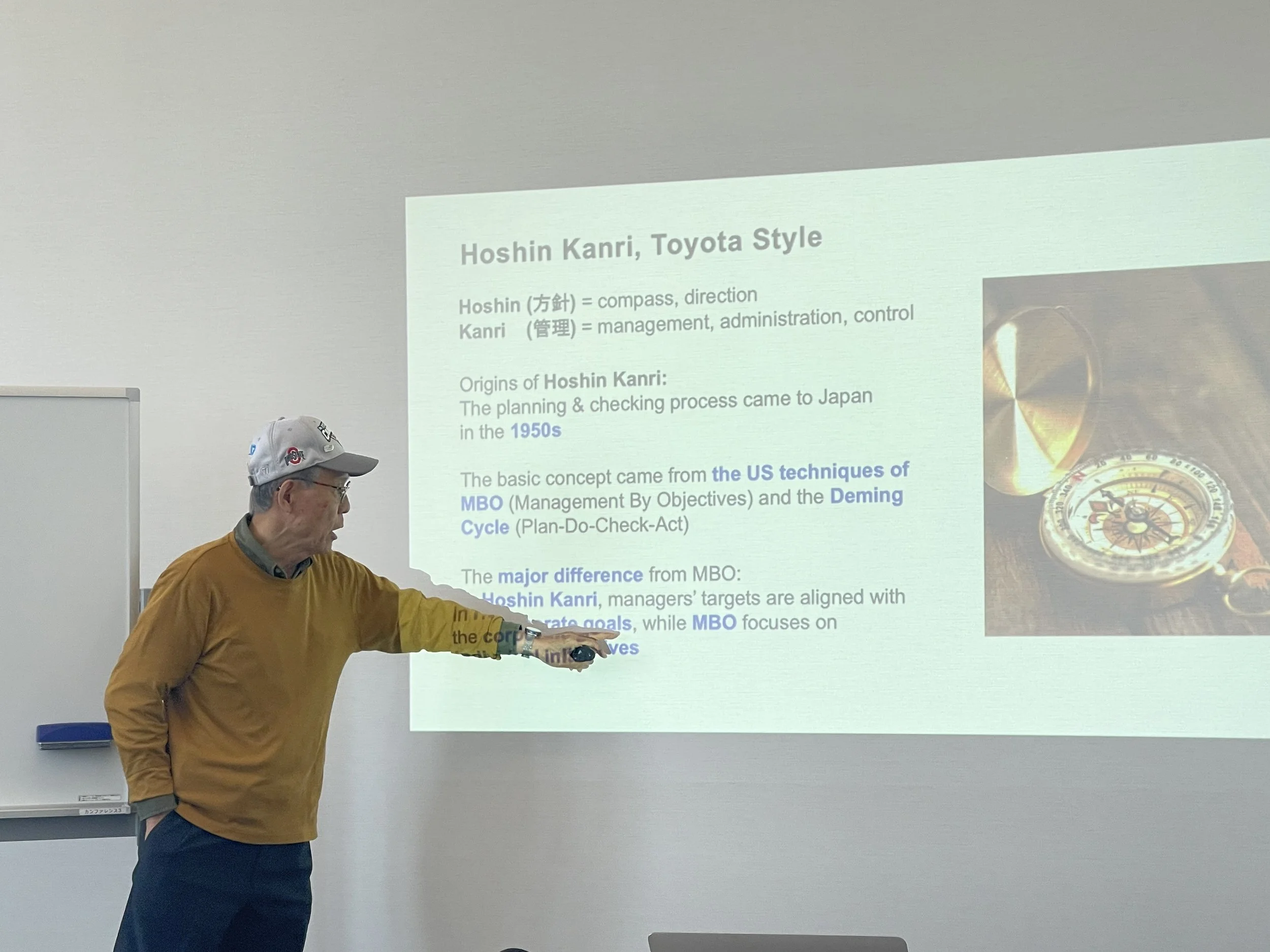

At Toyota, Hoshin Kanri played a crucial role in leadership. Hosin Kanro makes everyone feel part of the Toyota team.

MBO focuses on goals, while targets are aligned with them. Deming's ideas influenced Toyota.

Facts are more important than assumptions. Go to Gemba, 5S, and Meiru-ka (visualization).

The bad news first. No problem is a problem (Ohno). According to Sidney Dekker, the safety culture is one in which employees can tell managers bad news.

Respect your employees. The respect idea was introduced by Toyota President Fujio Cho, according to Mr. Yoshino.

Establish an open culture. He said 80% of Toyota leaders he worked with for over 40 years listened more than they talked.

Wait to provide subordinates with answers. The analysis aligned with Mike Rother's analysis of Toyota in Toyota Kata. This is what Rother refers to as Coaching Kata.

Optimize globally, not locally. Dr. Goldratt's Theory of Constraints emphasizes this principle.

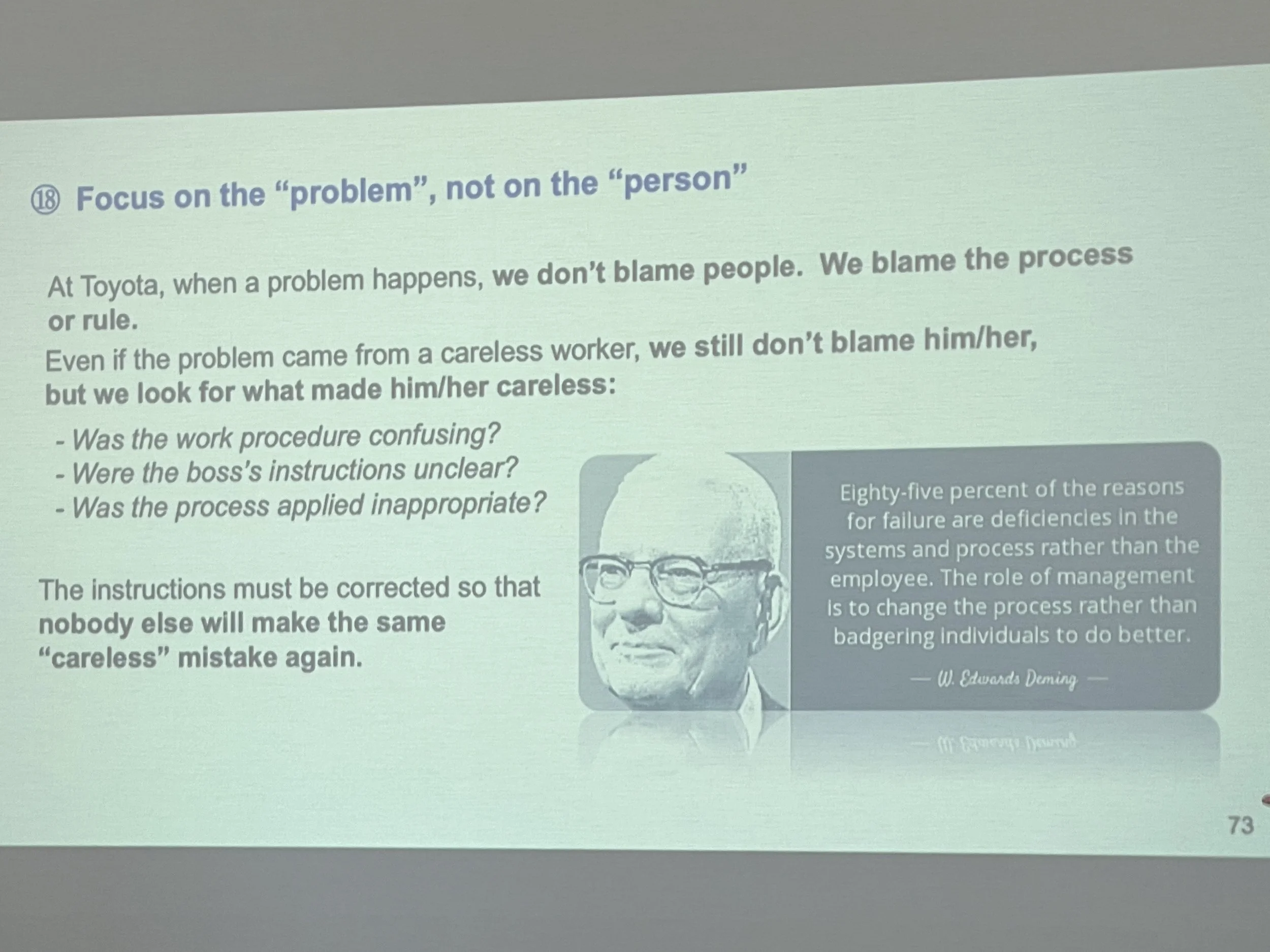

I had to get Mr. Yoshino’s Deming Slide in

We drove to Avex after lunch. Precision components are made by AVEX, mainly for Toyota. The company supplies Toyota and other companies at the tier-2 level. We heard from third-generation owner Takenori Kato about the company's history. In 1949, Avex was founded. Takenori Kato's grandfather, Avex's founder, worked directly with Aisin (Avex's tier-1 client) when Aisin and Toyoda were in the loom business. Avex originally created parts for Aisin sewing machines. Aisin is famous for the 1997 Toyota Group and the Aisin Fire. Interestingly, Aisin and Denso were spun out of Toyota in the late 1940s.

Group Trip to Avex - Takenori Kato is in the Bottom Middle

Here are some interesting takeaways:

At Avex, the president wore the same uniform as all the workers: no suit and tie. All shop floor technicians wore color-coded hats. The idea is to help identify how to help another technician best. A great example is that Avex hires handicapped technicians to work on the shop floor with a different colored cap. They do this to help the handicapped technician if they need it. They are also sensitive to this procedure; they talk to the technician's parents before they hire them.

Mr. Yoshino commented that Takenori Kato was a serious leader on the bus ride back to the hotel. Mr. Yoshino said big things can happen if the leader is serious.

Takenori Kato described how Avex deals with defects. They never blame to person; it's always the process. This aligns with Deming's 94% rule. In Mr. Yoshino's lecture, he also said that Toyota also lived by this rule.

In 2017, Avex celebrated its 75th anniversary and aims to reach its 100th anniversary. Japanese companies are known for their preference for long-term steady growth over short-term profits.

The average age of the workers is 30, and 50% are female.

In addition to creating jobs for the local community, Avex is very community-focused. Avex never layoffs employees and uses this as a bond of trust between employees and the company.

Most of their employees are high school and university students from the local area. Their parents celebrate the initial enrollment of the employees. New employees are asked to buy their parents a gift upon receiving their first paycheck.

Takenori Kato observed that over 70% of the cars were electric in Shanghai China. Moreover, the USD cost of these cars is around $30k, and they appear comparable to nondomestic EVs selling for around $60k. He argues that the traditional automotive supply chain is in danger in his meta point.

Avex has expanded beyond automotive into dentistry tools, fishing equipment, and bicycles. They have a philosophy based on the idea what you build now will not exist in the future.

Avex focused on Kaizen during the pandemic. According to Mr. Takenori Kato, Kaizen is not an event; it is a way of doing things.

In addition to refurbishing and rebuilding their equipment, they write their software as a cost-saving process. Technicians maintain machines. Kato described the machines as their babies.

In addition, Avex relies heavily on Hosin Kanri, and every employee has their own Hoshin that aligns with Avex's goals. Additionally, they practice quality control circles.

According to Takenori Kato, managers should spend 50% of their time in the Gemba, 30% on Kaizen, and 20% on employee development. The Gemba is where we make money, according to Kato.

My head is spinning with information. There's so much more I will need to dissect when I get back home. I can't imagine how much more we will learn, given we have four more days of this.