Day Two - Katie Anderson's Japan Study Trip (Part 1)

It was a busy day today. We left the hotel at 9:15 am and returned at 6:30 pm. Isao Yoshino joined us on the bus, and today's tours were honored by his presence. The highlight of my day was asking Mr. Yoshino what Dr. Deming's impact was on Toyota during the bus ride. Katie set up multiple microphones on the bus so the conversation could continue while traveling between destinations. Some of the Lean community in the US have minimized Dr. Deming's impact on Toyota. Several prominent scholars have told me that Dr. Deming did not impact Toyota. I will respond to Mr. Yoshino's answer in a future blog. However, I can tell you that his response was crystal clear. The impact he had was huge and direct. Dr. Deming's influence was well-known when Mr. Yoshino joined Toyota in 1966.

Glenn Wilson and ME in the lobby with the first working model of the circular loom.

Glenn Wilson, a friend, and author of the DevSecOps book, asked a follow-up question about Dr. Juran. In response, Mr. Yoshino said he was unaware of Dr. Juran's impact. Juran significantly impacted Japan and Toyota, but Dr. Yoshino was more aware of Deming's influence than Juran's. The main point is that Mr. Yoshino was not an American scholar who visited Toyota in the late 1980s and 1990s; he worked at Toyota for 40 years.

History of Looms

The museum was our first stop of the day. Toyota Commemorative Museum of Technology and Innovation was our destination. It is the museum you should visit if you are visiting Nagoya. When I visited Nagoya in 2019, I missed it. Firstly, it is the original Sakichi Toyoda's Toyoda Automatic Loom Works site. Like Thomas Edison in America, Sakichi Toyoda is the father of the Japanese industrial revolution. Museum's first half is dedicated to loom industry history. In addition to cotton spinning demonstrations, you will see a live replica of a Jidoka (mistake-proof) loom. A non-stop shuttle-change automatic loom (Type T loom) was created by Sakichi Toyoda in 1903. When a needle breaks, a weight drops, and the loom automatically stops.

non-stop shuttle-change automatic loom (Type T loom)

Toyota's automotive business is featured in the second half of the museum. Yoshino told us about Toyoda's renaming to Toyota. Toyoda's original Japanese symbols used ten strokes. Toyota's new symbol uses eight strokes instead of ten. According to Mr. Yoshini, this change is also a symbol of Toyota's philosophy. As well as being more efficient to write eight strokes (less waste), the new logo symbolizes a relationship between eight and ten. Hence, the gap between eight and ten illustrates Toyota's commitment to continuous improvement.

Toyoda (Ten Strokes)

Toyota (Eight Strokes)

I’ve included serval images from the tour.

Early Model AA

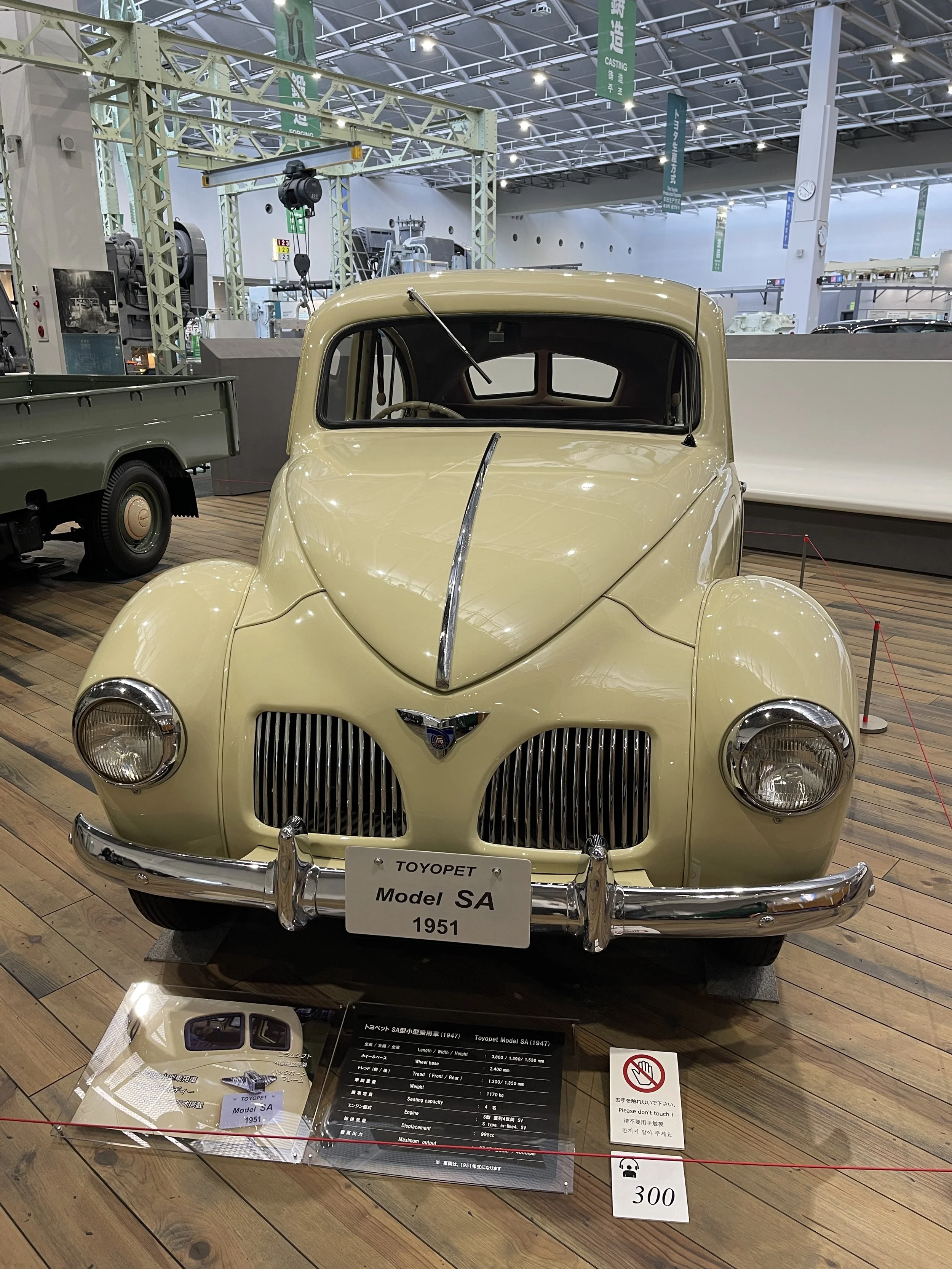

The Toyopet (see my blog about the Toyopet)

A replica of the Toyota implementation of Ford’s assembly line.

After the museum visit, we made two more stops. I will discuss these visits in the next part 2 and part 3 blogs.

Here's part 2:

https://www.profound-deming.com/blog-1/day-two-katie-andersons-japan-study-trip-part-2